Steel billet reheating furnace

Features:

| Application | Steel billet reheating, heating and rolling |

| Power | 100KW-10000KW |

| Non-standard |

Professional Customization |

Product Detail

Application Video

Product Tags

Product Name: Steel billet reheating furnace

Typical Applications:

Steel billet reheating furnace developed and manufactured by Forever is used for steel billet reheating, square billet heating,steel billet continuous casting and rolling, which has been recognized by customers from home and abroad.Especially Taiwan and Vietnam customers buy our steel billet reheating furnace repeatedly.

Steel billet reheating furnace field application:

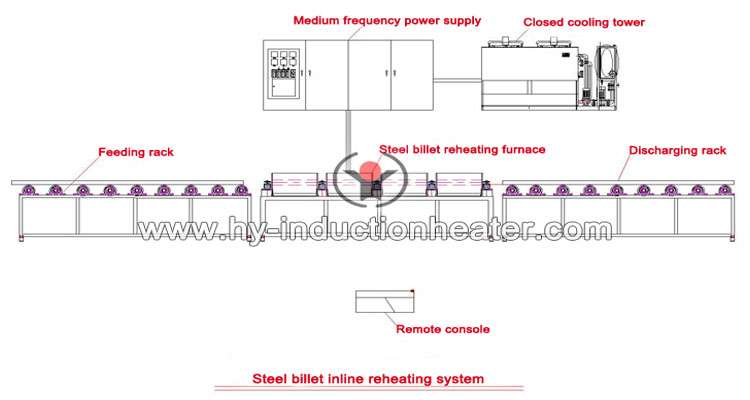

Steel billet inline reheating system

Design conditions and basic parameters for steel billet reheating furnace

● The heating steel material: carbon steel, alloy steel

● Steel billet size: 135mm×135mm×6000mm;

● Steel billet maximum camber before charging furnace:≤ 3mm/M

● Steel billet temperature before charging furnace:surface≥800℃,inside 900℃~950℃

● Tapping temperature:1050℃

● Production capacity:100 T/T

● Electricity consumption per ton:≤ 40~50kw

● Roller speed:~12.5m/min (0~13m/min Frequency conversion speed)

● PLC automatic control for the whole heating process; Timely displaying the heating production quantity records

● The water cooling roller and guide roller material: Non magnetic heat resisting stainless steel

Forever can not only supply good quality billet induction heating furnace but also we are concentrating on energy saving and automation development of induction heat treating equipment for 16 years.More details,please check http://www.hy-inductionheater.com/billet-induction-heating-equipment

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.